Routine maintenance, including cleaning, lubrication, and part replacements,

helps prevent premature wear and tear on machinery components. This prolongs the

lifespan of the equipment, reducing the need for costly replacements and upgrades.

Cost Savings:

Although maintenance requires an investment of time and resources, it ultimately

saves money by reducing the frequency and severity of repairs. Preventive maintenance

is often less expensive than reactive repairs, especially when considering the potential

costs of equipment failure during critical times, such as planting or harvesting seasons.

Improved Safety:

Well-maintained equipment is safer to operate for farm workers. Regular inspections can

identify potential hazards or faulty components that could lead to accidents or injuries.

By addressing these issues promptly, maintenance helps create a safer working environment

on the farm.

Optimized Performance:

Properly maintained farm equipment operates at its intended performance levels, delivering

consistent results in tasks such as planting, harvesting, and field preparation. This

reliability allows farmers to meet deadlines and maximize yields without disruptions caused

by equipment malfunctions.

Compliance with Regulations:

In many regions, there are regulations and standards regarding the maintenance and

operation of

agricultural machinery, particularly concerning safety and environmental concerns.

Keeping equipment well-maintained helps ensure compliance with these regulations,

avoiding fines or penalties for non-compliance.

Preservation of Resale Value:

If and when the time comes to upgrade or sell farm equipment, well-maintained machinery typically

commands higher resale values. Buyers are willing to pay more for equipment that has been properly

cared for, as it is perceived to be in better condition and less

likely to have hidden issues.

Environmental Benefits:

Properly maintained equipment often operates more efficiently, which can

lead to reduced fuel consumption and emissions. Additionally, preventing leaks or spills through

regular inspections and maintenance helps minimize environmental impact, protecting soil, water,

and air quality on the farm and surrounding areas.

-

Equipment We train on

- Tractors

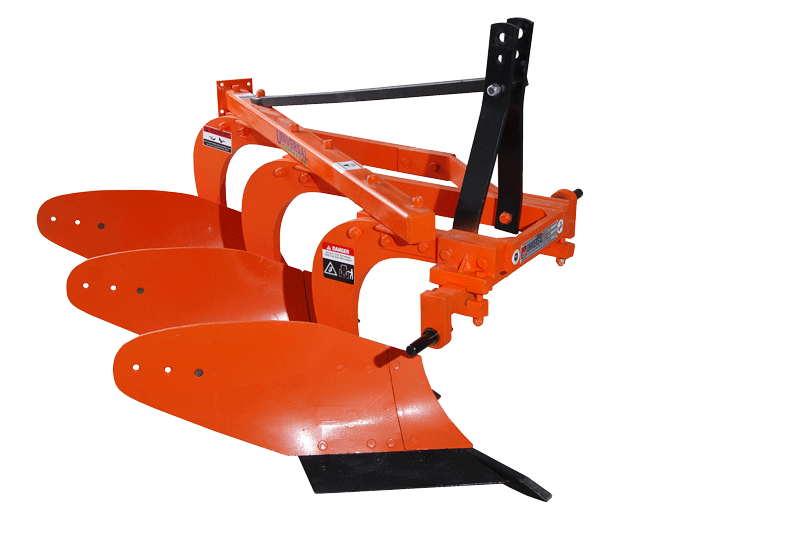

- Primary tillage equipment

- Secondary tillage equipment

- Tertiary tillage equipment

- Planting equipments

- Crop protection equipments

- Harvesting equipment

- Transportation equipment